UNS N07718

W.Nr 2.4668

Inconel 718 Alloy

- AMS 5596

- AMS 5597

- ASTM B670

Our wide capabilities give us a unique ability to supply all of your Inconel 718 needs.

description

Inconel 718 Description:

Inconel® 718 is an age-hardenable Nickel-Chromium-Columbium (Niobium)-Molybdenum alloy with high strength, corrosion-resistance, and good fabrication characteristics. Inconel® 718 has high tensile, yield, and creep-rupture properties at high temperatures up to 1200°F (650°C).

applications

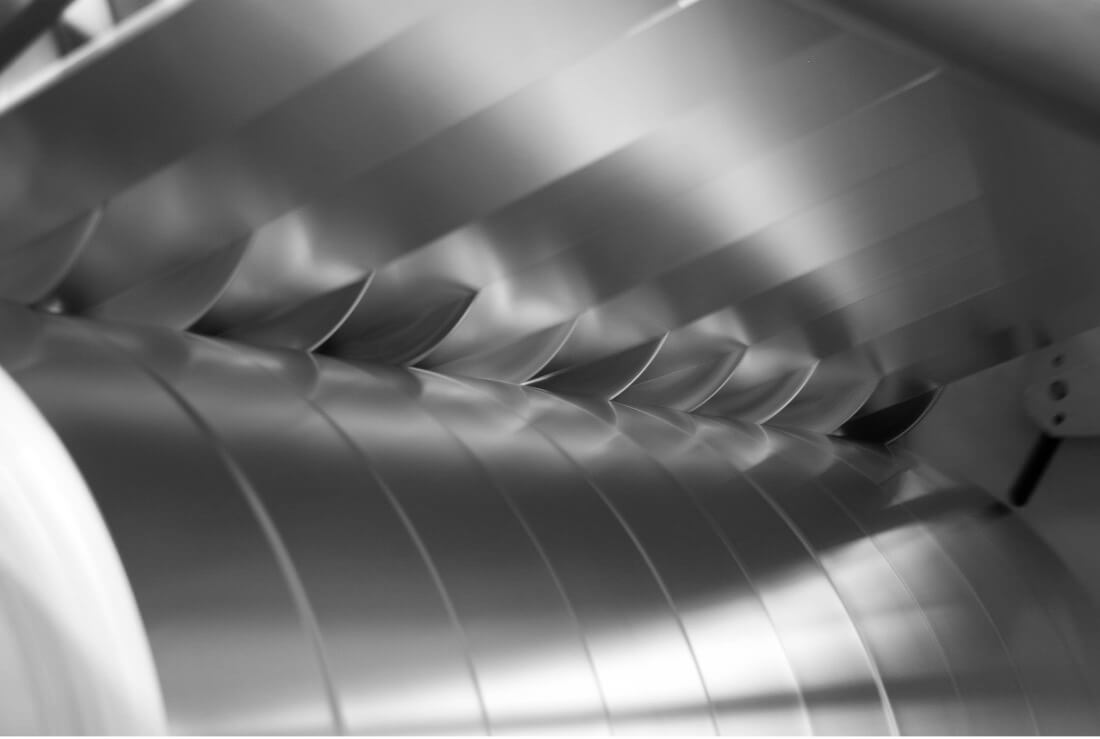

Inconel 718 Uses & Applications:

Alloy 718 combines properties which make it suitable for a variety of fabricated component applications in both aircraft turbine engines and land-based turbines. These include seals, bellows, and many types of stamped metal components. The alloy is used in downhole and well head components for oil and gas wells.

Industries supplied include:

- Oil & Gas Extraction

- Nuclear

- Aerospace

- Defense

- Automotive

Nominal Composition

| C | Mn | Si | P | S | Cr | Ni | Mo | Nb | Ti | Al | Co | Fe | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| MIN | – | – | – | – | – | 17.00 | 50.00 | 2.80 | 4.75 | 0.65 | 0.20 | – | – |

| MAX | 0.08 | 0.35 | 0.35 | 0.015 | 0.015 | 21.00 | 55.00 | 3.30 | 5.50 | 1.15 | 0.80 | 1.00 | BAL |

Physical Properties

| At 70°F | At 20°C | |

|---|---|---|

| Density | 0.296 lb./in³ | 8.19 g/cm³ |

| Modulus of Elasticity (E) | 29 x 10³ ksi | 200 GPa |

| Modulus of Rigidity (G) | 11.6 x 10³ ksi | 80 GPa |

| Coefficient of Expansion | 7.7 microinches/in.-°F (°F) | 13.9 μm/m-°C (°C) |

| Electrical Resistivity | 47.5 μ ohm.in | 121 μ ohm.cm |

| Thermal Conductivity | 79 Btu-in./ft.²hr.-°F | 11.4 W/m-K |

Typical Mechanical Properties

| Condition | Heat Treatment | Tensile Strength | Suggested Operating Conditions |

|---|---|---|---|

| Annealed | 1800°F (980°C) | 120 – 140 ksi (830-965 MPa) | -330°F to 1200°F (-200°C to 650°C) |

| Spring Temper | – | 180 – 230 ksi (1240 – 1585 MPa) | -330°F to 1200°F (-200°C to 650°C) |

| After Precipitation Heat Treat | Per AMS 5596 | 190 – 240 ksi (1310 – 1655 MPa) | -330°F to 1200°F (-200°C to 650°C) |

* INCONEL® is a registered trademark of the Special Metals Corporation group of companies.

Limitation of Liability and Disclaimer of Warranty:

- The content in these data sheets is provided primarily by third-party melting mills and is provided for reference only. It is not intended for engineering or design.

- Applications may be discussed, however, Combined Metals Company, LLC, does not recommend or endorse any material for any particular end use or application.

- The data included in this data sheet are typical values and may vary.

- Combined Metals Company, LLC, makes no representations or warranties, express or implied, as to the accuracy, completeness, condition, suitability, performance, fitness for a particular purpose, or merchantability of any information contained in any data sheet.

In no event will Combined Metals Company, LLC, be liable for any damages whatsoever arising from the use of the information included in the data sheets.

Benefits of Working with Combined Metals

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, nostrud exercitation ullamco laboris nisi. Lorem amet, consectetur adipiscing elit,

HELPFUL TOOLS

Coil Calculator

Choose a calculator to find coil weights, coil OD’s, coil footage, and PIW.

DEEP EXPERIENCE IN YOUR INDUSTRY

Serving Your Market

The Combined Metals Family of Companies

Explore Our Companiesget in touch

Questions? Contact Our Experts Today.

The Combined Metals Company mission is to safely produce and distribute the best value and the highest quality engineered stainless steel coil and sheet, specialty alloy strip, foil, and wire products and to deliver those products to customers around the world. Give us a call at (800) 323-0758 or fill out the form.

*denotes a required field.